Future solutions for the construction industry

As a start-up company, Block solutions has rapidly grown into one of the most interesting companies providing unique and innovative building solutions.

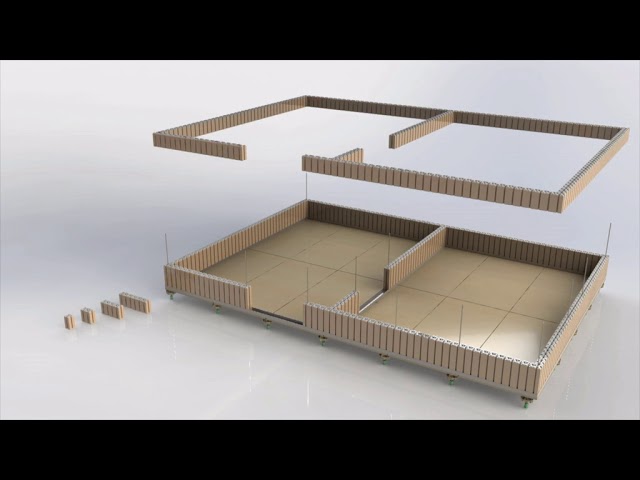

Representing world-class innovation from Finland, our product, an eco-friendly house built of modules, was born in 2017 after a long series of development. Our goal is to revolutionize the construction industry with our building technology and material. The easy-to-build, fast, sustainable and strong buildings enhanced with unique adjustability opens up a brand-new way of building houses.

Block solutions has a long-term international growth strategy. Our main market areas are emerging markets, but we are also going to expand our business to other regions.

The cost-efficient and sustainable life-cycle cost approach is the foundation for the new era of affordable housing.

Smart product innovation

Future solutions for different needs in the construction industry.

Our story

In the year of 2016 Markus Silfverberg was having a discussion with the UN regarding especially the crisis areas in Africa and the urgent need to find temporary shelter for millions of people. The practical need was to find mobile, affordable modules that could be easily built and would be better than temporary tents. Other criteria were the common lack of electricity and tools and that the shelters needed to be lightweight. The task was demanding, but Mr Silfverberg decided to give it a try.

He started developing the idea of a new building concept alone, then brought it up with some of his family friends, ones with an understanding of technology and business. They all shared the mindset that anything is possible. Saw tremendous potential behind the idea and a team of six like-minded people was established. “Quality and environmental issues are paramount to us, and the development of the product was based on that.”

In addition, Mr Silfverberg also had decades of experience and expertise on environmental issues, different rawmaterials and the building industry.

“Our vision is to disrupt the entire construction industry with our innovative solution and material. We are creating a better tomorrow by creating sustainable communities around the world.”

Ecological raw material

We are using local raw materials like recycled plastics for the Blocks. In Europe we have decided to use biocomposite as the raw material for the Blocks. Biocomposite which can contain up to 50% of organic fibers and 50% recycled polypropylene from verified and trusted origins to ensure the safe use. The carbon footprint of the used raw materials are close to zero. Comparing the Blocks with conventional building materials like concrete, the carbon footprint can be up to 20 times lower.

The opportunities of the building method of the future

There is a wide-spread interest in the Blocks both in industrialised and in emerging markets. People recognize the potential for permanent housing in, for example, Namibia and Rwanda.

“We never stop imagining what else we could do with the Blocks. The possibilities are endless.”

Mobile house built in eight hours with a rubber hammer and a wrench

Mr Silfverberg’s team patiently kept on testing new versions of the Blocks. During the initial period of one year, numerous 3D-printed versions were built, until the team figured out the right shape and method of production. A miniature house was built in the garage. “We were able to produce very lightweight Blocks that were easy to assemble. Nearly anyone, together with another person, can build a house in just eight hours, with only a rubber hammer and a wrench.” Thanks to the material and technology, the cost of building stays low. Also, the house can be easily dismantled, rebuilt somewhere else, rooms can be added and modified.

The innovative building method has been presented around the world on numerous occasions. The reception has been overwhelmingly positive. “A big thank you to our partners, Business Finland, Finnpartnership and the Foreign Ministry of Finland, who have guided us in the right direction and opened doors to us.”

At the moment, Block solutions is establishing license production facilities around the world. We want to give opportunities for partners to become local licensees and to commit to abide to the company policy of gender equality and equal pay. The licensee package provides the local entrepreneur with all necessary production machinery for starting their own business: an injection molding machine, molds, trainings and a high-revenue business opportunity. With our business model we want to support job creation in emerging markets, create better opportunities and create prosperity in the area and for the families.

.png)